About Drilling Rigs Functions

Drilling rigs are specialized drilling equipment used in geological exploration, mineral prospecting, geotechnical engineering, and water well drilling, serving key functions including:

- Extracting subsurface core samples

- Analyzing geological formations

- Evaluating resource deposits

- Constructing water wells and foundation boreholes

- In-situ testing and environmental monitoring

- Hydrological monitoring for emergency disaster relief

Full Hydraulic Crawler Core Drilling Rig

The fully hydraulic crawler core drill uses an infinitely variable speed hydraulic motor to control the rotation or feed of the drill rod. It is designed for efficient coring in complex terrains. It combines mobility with deep drilling capabilities and is equipped with a double-layer core tube, a rope coring system, a digital monitoring screen, etc.

Your Trusted Drilling Rigs Manufacturer in China

If you have any questions about the selection of drilling rigs, Shandong Palion, as a professional drilling rig manufacturer in China, is always ready to provide you with professional advice. We have many years of industry experience, and our product line covers a variety of models of drilling rigs to meet the needs of different working conditions. Our professional technical team will recommend the most suitable solution for you based on your specific needs.

Drilling Rigs by Features

Drilling rigs can be divided into core drilling rigs, water well drilling rigs, mechanical top drive drilling rigs, etc., according to their functions.

Core drilling rigs can fully preserve the lithology of the formation and have a high core recovery rate.

The water well drilling rig can drill to a depth of 50~500 meters and is suitable for a wide range of formations.

Mechanical top drive drilling rig can drive the drill pipe to rotate, without releasing the drill pipe, and can drill continuously.

The fully hydraulic core drill has a high coring rate and can achieve stepless speed regulation.

Exploration core drilling rigs can achieve hole depths of 50 to 3,000 meters and are suitable for different rock formations.

Hydraulic deep well drilling rigs have the advantages of strong power, precise control, and adaptability to complex formations.

Diamond core drilling rig is suitable for super-hard rock formations, hydraulic speed regulation, and protection of core structure.

Reverse circulation drilling rigs are mainly used for large-diameter deep hole drilling and are suitable for mineral exploration, water well construction, pile foundation engineering, etc.

Drilling Rigs by Depth

Drilling rigs can be divided into down-the-hole drills, medium-deep hole drills, and deep hole drills according to the drilling depth.

Shallow Hole Drilling Rig

Shallow Hole Drilling RigThe down-the-hole drill has a simple structure, strong mobility and fast drilling speed.

Medium Depth Drilling Rig

Medium Depth Drilling RigThe medium-deep hole drilling rig is equipped with a feeding mechanism and a pressure stabilizing system, and a top drive device is optional.

Deep Hole Drilling Rig

Deep Hole Drilling RigThe deep hole drilling rig is equipped with a high-power power system and an automatic pipe laying device.

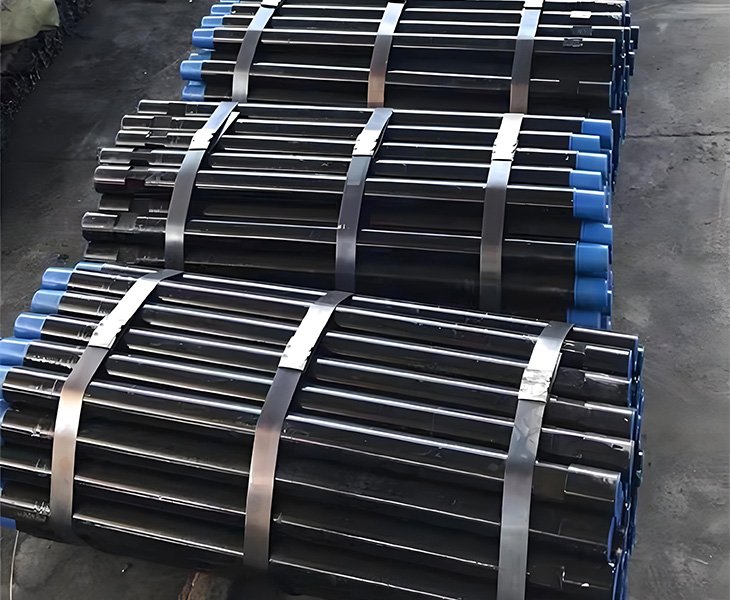

Drilling Rig Drill Pipe

The drill rods produced by the company are made of conventional materials DZ40, 45# steel, hard rock materials R780/DZ50 alloy steel, etc., depending on the working conditions. They adopt a hollow seamless design and support sampling without lifting the drill.

Drilling Rig Bits

There are many kinds of drill bits for drilling rigs, including carbide drill bits suitable for soil, shale, and medium-hard sandstone, diamond drill bits suitable for granite and quartzite, and toothed roller cutter bits.

Selection Criteria

It is necessary to clarify whether the construction geology is soil, sand, gravel or rock, so as to select the appropriate drill bit.

According to the drilling depth, how much drill rod should be matched.

According to the hole size, match the diameter of the drill bit.

Company Advantage

Pailien has high-end drilling technology and R&D capabilities. Key components are made of high-strength materials and can adapt to complex and extreme working conditions. The equipment meets international safety and environmental standards.

Core Drilling Rig Construction Scene

Core drilling rigs are mainly used in mineral resource exploration, engineering geological surveys, hydrogeological surveys, and geological science research.

In the chromite exploration in South Africa, the project used a PLE-1600 fully hydraulic drilling rig equipped with a rope coring system. The construction team operated in accordance with the specifications and achieved a core recovery rate of 95%, achieving integrity and efficiency in coring.

China’s Qinghai copper mine exploration project uses the PLE-1600 exploration core drilling rig, which is used for the Mesozoic ultrabasic rock formations and is equipped with a diamond drill bit to ensure a mechanical drilling speed of ≥1.2m/h. The core samples are analyzed by ICP-MS at the Natural Resources Testing Center.

More About Drilling Rigs

- Data Sheet

| Rig type | PLE-1600 | PLE-2000 |

| Weight | 10000kg | 12000kg |

| Dimension(transport) | 5900*2100*2400mm | 6100*2200*2500mm |

| Dimension(working) | 5900*2650*8100mm | 5300*3600*8100mm |

| Drilling angle | 45-90° | 45-90° |

| Drilling depth BTW | 1800m | 2200m |

| Drilling depth NTW | 1600m | 2000m |

| Drilling depth HTW | 1400m | 1800m |

| Drill head lift force | 460kN | 600kN |

| Drill head feed force | 230kN | 300kN |

| Rotary speed RPM | 0-1100rpm | 0-1100rpm |

| Max.Torque | 4000N.m | 5000N.m |

| Drill head feed stroke | 3500mm | 3500mm |

| Drill mast slide stroke | 1200mm | 1200mm |

After-Sales Service

As a professional drilling rig manufacturer, we can provide fast technical support and guidance services, a professional engineer team is online all day, regular equipment inspection and maintenance services, technical guidance on improving core recovery rate, basic operation specification training, equipment maintenance training, special formation drilling training, spare parts service life tracking management, and lifelong technical support guarantee.

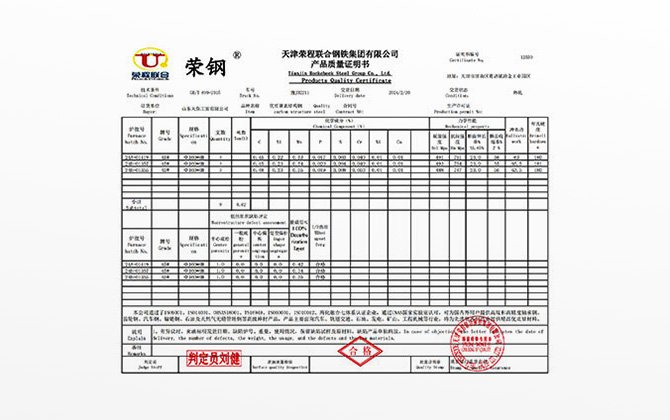

Our company has core technologies with independent intellectual property rights, intelligent and automated automatic deviation correction, and remote monitoring systems; it can cope with complex geological rock formations, and its modular design can adapt to a variety of working conditions. The company has various patent certificates, quality inspection certificates, CE certificates, etc. At the same time, it provides integrated services such as equipment selection, construction training, and maintenance optimization according to customer needs.

The drilling rig can be used in a variety of geological conditions. According to the analysis of practical conditions, it is currently mainly suitable for the following geological conditions: hard base (granite, tuff, etc.), loose and broken strata (sand and gravel layers, fault zones), and soft soil strata (clay, silt, etc.).

Core drilling rigs are mainly powered by internal combustion engines (diesel engines) and equipped with diesel generator sets to adapt to outdoor environments without power grids. The drilling rig’s drill arm, thruster, rock drill and other actuators all use hydraulic oil as the power medium.

The selection of the appropriate drilling rig type can be based on the following aspects: drilling depth and hole diameter, hardness adaptability of the rock formation, power and energy consumption, project construction period requirements, complexity of the terrain, etc.