Advantages of Our Water Well Drilling Rigs

Water well drilling rigs have been developed for many years and have competitive advantages in terms of adaptability, power, and efficiency:

- Increased efficiency by utilizing air impactors for crushing

- Zero pollution, explosion-proof, and safe

- The low energy consumption of the air compressor saves energy

- Adaptation to a variety of complex environments

Your Trusted Water Well Drilling Rig Supplier in China

As a water well drilling rig manufacturer, we have always been committed to technical services and product optimization to help customers solve various problems encountered during construction.

We can solve efficiency problems by switching between rotary, percussion, and rotation modes during construction to cope with complex geological formations such as hard rock, sandstone, and clay.

At the same time, we optimize the power system and equip it with variable frequency technology to adjust power according to load. To cope with water shortages in certain areas, we provide pneumatic water well drilling rigs that do not rely on mud circulation and are suitable for arid regions.

Water Well Drilling Rig by Features

Suitable for medium-hard to hard strata, commonly used for large-diameter water wells, cutting through strata using a rotating drill bit.

Suitable for hard formations such as granite, powered by a diesel engine, and equipped with high-strength drill pipes connected to the drill bit.

Suitable for emergency water supply, field operations, or decentralized drilling projects, integrated onto a truck or tracked chassis, offering high mobility.

Suitable for alternating soft and hard strata or fractured formations, combining rotary and impact functions to accommodate more complex geological conditions.

Suitable for high-precision or deep well projects, primarily using hydraulic drive, precise operation, and capable of automated control.

Suitable for geothermal resource development or ultra-deep wells, specifically designed for high-temperature and deep well conditions, using high-temperature-resistant materials and reinforced structures.

Suitable for rural household water supply or shallow water extraction in remote areas, using small-scale power drives and featuring a simple structure.

Deep well water well drilling rig are mainly adapted to various loose layers (such as clay, sand), medium and hard rock formations, the equipment has strong power.

Framework

Mainly consists of a power system, a drilling tool system, a hoisting, feed system, a rotation system, and a mud circulation system.

Powered primarily by air compressors, diesel engines, or electric motors to meet the power requirements of drilling platform operations, it converts mechanical energy into hydraulic energy to drive rotational, feed, and lifting movements.

Includes drill pipes, drill bits, and weight bars. Drill pipes are made of high-strength alloy steel, segmented for connection, and transmit drilling pressure and torque; drill bits are designed to adapt to various rock formations.

A high-pressure water pump delivers mud to cool the drill bit and carry away rock cuttings. The mud tank mixes and stores the mud, equipped with a mixer to prevent sedimentation.

The rotator drives the drill pipe to rotate, equipped with a hydraulic motor and infinite speed adjustment function. The chuck clamps the drill pipe and transmits torque, featuring anti-slip and quick-release design.

The derrick supports the weight of the drilling tools, with height determining the single drill pipe stroke. The winch raises or lowers the drilling tools via steel wire ropes, equipped with a braking system to ensure safety.

The control panel operates functions such as rotation, hoisting, and mud pump operations. Sensors continuously monitor parameters including drilling pressure, rotational speed, mud pressure, and well deviation.

Water Well Drilling Rig Air Compressor

The water well drilling rig air compressor converts mechanical energy into high-pressure air energy, greatly increasing drilling speed by 2-3 times compared to traditional methods. It does not require mud circulation, saving water resources and reducing environmental pollution. The equipment uses variable frequency control to regulate air volume, avoiding no-load energy consumption, and recovers waste heat for wellhead frost protection.

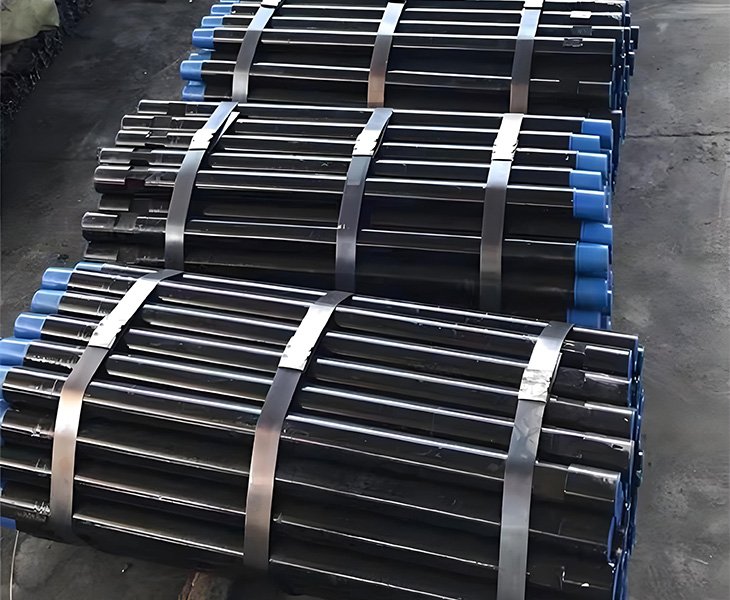

Water Well Drilling Rig Drill Pipe

The Water well drilling rig drill pipe is made of alloy steel, which undergoes tempering heat treatment to achieve a hardness of HRC28-32, thereby improving the material’s toughness and fatigue resistance. The surface is treated with chrome plating or nitriding to enhance the equipment’s wear resistance.

Guide to Procuring Water Well Drilling Rig

When selecting a water well drilling rig, it is necessary to choose based on specific working conditions, such as geological conditions, drilling diameter and depth requirements, terrain conditions, etc.

Once the specific operating conditions of the water well drilling rig have been determined, the appropriate water well drilling rig model can be selected, such as drill bit size, drill rod thickness, and matching power.

When placing an order for a water well drilling rig, it is necessary to double-check the drilling parameters, technical agreement, and configuration requirements.

Company Advantage

As a professional water well drilling rig manufacturer, the company possesses efficient drill bit design and intelligent control system technology. It also provides customized solutions for special geological formations such as gravel layers, fractured zones, and hard rock. Key components are made of industrial-grade materials, ensuring a longer service life. Additionally, the company optimizes power matching performance, achieving drilling speeds 15% to 20% higher than traditional drilling rigs. It offers rapid response times and provides comprehensive training throughout the entire process, including operation, maintenance, and safety.

Your Water Well Drilling Rigs Supplier

As a water well drilling rig manufacturer, we can provide special drilling rig solutions according to customer needs, such as drilling depth, geological conditions, etc.; assist customers in choosing the right drilling rig model and construction technology; provide training (on-site or remote guidance) in the use of the equipment, maintenance and safe operation; on-site or remote guidance from the manufacturer’s technicians for installation and commissioning; provide warranty services for core components; recommend maintenance programs to Extend the life of the equipment.

In the actual production, the main reasons that lead to the wear of water well drilling rig drill bits are: hard geology, material and working conditions do not match, too high speed or too much feed pressure. This can be prevented and improved by replacing the drill bits and adjusting the parameters.

Pneumatic water well drilling rig mainly includes power system, drilling system, slag draining system, maneuvering system, auxiliary device, walking system, etc. It relies on compressed air for driving, and it is suitable for drilling water wells in water-scarce areas, hard rock formations, or in special environments, with a wide range of applications.

The causes of jammed and buried drilling in fully hydraulic water well drilling rig may be due to the collapse of the hole wall, accumulation of drill cuttings, encountering expansive clay layer or sudden surge of sand or groundwater that leads to the destabilization of the hole wall, which need to try to reverse the drilling rod in time, inject lubricating paddle, and need to be dealt with in sections in serious cases.

Deep water well drilling rigs need to be prepared for surveys: geological profiles need to be obtained, electric logging, pressurized head heights, location of fault zones, etc.

When selecting a pneumatic water well drilling rig, you need to consider the drilling depth requirements, compressed air supply capacity, equipment mobility requirements, formation lithology characteristics and so on.