Competitive Advantages of Water Drilling Machine

After years of development, water drilling machines have competitive advantages in performance, power, and operating efficiency:

- Utilizing a high-torque hydraulic motor, the hydraulic control system utilizes a brand-name diesel engine and large-diameter hydraulic cylinders for improved efficiency.

- A unique shock absorber design and a centralized operating system ensure easy operation.

- The brand-name diesel engine utilizes a two-stage air filtration system to protect the low-energy air compressor, saving energy.

- It can operate effectively in both soil and rock layers, adapting to various complex environments.

Your Trusted Water Drilling Machine Supplier in China

As a water drilling machine manufacturer, we have developed a series of core technologies over over a decade: an intelligent power matching system ensures optimal performance in any formation, achieving faster drilling and lower fuel consumption; the use of advanced hydraulic technology, equipped with a high-torque hydraulic motor and large-bore hydraulic lever, allows for easy drilling in complex conditions from soft soil to hard rock; and the use of conventional ball-tooth drill bits for impact rotary drilling in hard rock formations, achieving high-speed hole creation.

Water Drilling Machine by Features

Using air compressor power to repeatedly lift the drill bit and then let it fall freely, effectively impacting and breaking the rock.

Drilling is achieved by rotating the drill rod and drill bit using mechanical power, cutting and grinding the rock.

This rig combines percussion and rotary drilling methods, allowing you to choose the appropriate method based on the customer’s geological conditions.

This type of rig, mounted on a crawler chassis, offers strong off-road capabilities and can adapt to a variety of challenging terrain.

Full hydraulic system drive, precise control, smooth transmission, and stepless speed regulation.

Transmitting power through mechanical structures such as gearboxes is a traditional way of power.

The drilling depth is relatively shallow, within 200 meters, and is mostly used for household applications and farmland irrigation.

The drilling depth is relatively deep, about 600 meters and the deepest can be 1000 meters. It is mostly used in special fields such as geological development and mineral exploration.

Framework

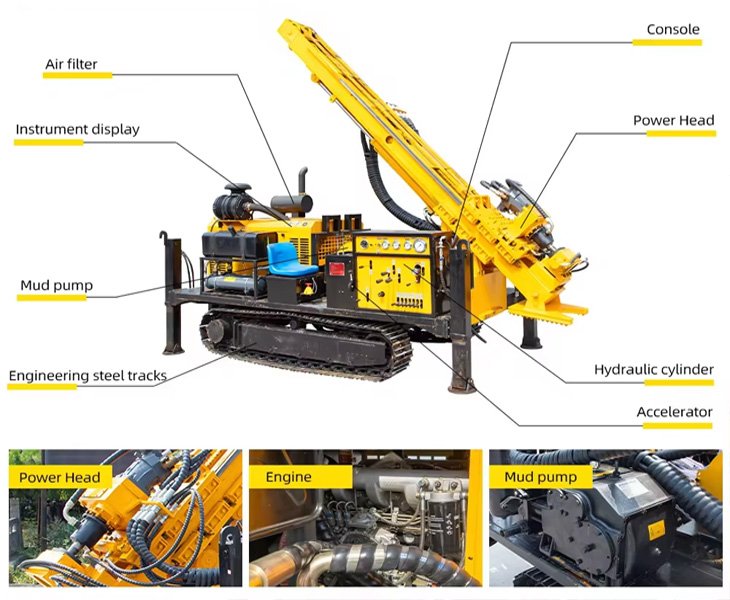

A water drilling machine mainly consists of a Power system, a Hoisting system, a Control system a Drilling system

It uses a diesel engine or air compressor to convert fuel electricity or air compressor mechanical energy or hydraulic energy and air energy to drive the hydraulic system to work.

It is composed of drill pipe, drill bit, mud pump, etc. The power system directly drives the drill pipe and drill bit to rotate and grind the rock, or it is used in conjunction with a down-the-hole hammer to crush the rock with high-frequency impact, and the rock debris is brought out of the wellhead through the mud pump.

The derrick is used as support, the winch is used as the power core, and the wire rope is rotated to lift the drill rod to achieve the purpose of replacing the drill rod.

The control system receives instructions through the console, collects information through sensors, makes decisions through computers, and finally drives the mechanical system to complete the process, which has higher efficiency and accuracy.

The circulation system uses a mud pump to pump mud to the bottom of the well through the drill pipe, and then returns to the surface with rock debris. After purification, it is recycled to achieve the functions of cleaning, lubrication and cooling, which is the key to maintaining the stability of the well wall.

The crawler walking system is made of rubber or steel plate material. The driving wheel drives the walking, and the control motor adjusts the walking speed and direction. It has strong stability and can pass through various complex terrains and is suitable for different working scenarios.

Water Drilling Machine Diesel Motor

The diesel engine drives the coupling to rotate by adding fuel and burning, and then drives the hydraulic pump (gear pump or plunger pump) to convert the mechanical energy of the diesel engine into high-pressure hydraulic energy. The energy is then transmitted to the hydraulic motor of the drilling rig through the oil pipe to drive the drill pipe to drill and transmit it to the hydraulic cylinder and other components to achieve drilling, lifting, and pressurizing actions. It is the core power hub of the water well drilling rig.

Water Drilling Machine Drill Pipe

The drill bit of a water drilling machine is the core component that directly contacts the ground and completes rock breaking and soil cutting. It is divided into diamond drill bits, roller drill bits, spiral drill bits, etc. Different drill bits are selected according to the customer’s geological conditions. This directly determines the efficiency and quality of drilling and is a key component of drilling.

Guide to Procuring Water Drilling Machine

Identify your needs and select the appropriate water drilling machine based on the actual geological conditions, rock or land, drilling depth and diameter, and budget.

After choosing the right water drilling machine, match the appropriate model of water drilling machine according to the diameter and depth of the hole, and communicate with the technicians about some necessary accessories such as drill rods and drilling tools.

After confirming the water drilling machine and model, determine the construction period and delivery date, and sign the contract.

Company Advantage

We have been deeply involved in the drilling rig industry for more than 10 years and have mature technologies in hydraulic systems, intelligent control, and power heads. We are able to optimize our drilling rig models for different geological conditions and produce core components in-house to ensure reliable quality and stable supply. We have CE certificates that comply with EU certification. Our customers are all over the world and have successful cases in complex working conditions. We also have a complete after-sales service system to provide professional after-sales maintenance for global customers.

Your Reliable Water Drilling Machine Manufacturer in China

As a water drilling machine manufacturer, we will tailor-make the most suitable drilling rig model and drilling tool configuration for our customers based on their geological conditions, drilling depth, diameter, and budget. We manufacture all our own drilling tools and provide long-term, stable accessory support. We offer a warranty for the entire machine, and an even longer warranty for key components. Installation and operating instructions will be provided upon shipment. If you encounter any technical issues, we can provide remote or on-site technical guidance.

First, it is necessary to determine the geological type of the drilling area, whether it is soil or a rock layer. Secondly, it is necessary to determine the target depth. Choose a suitable chassis according to the terrain. For complex terrain, choose a crawler drill rig. For areas with relatively flat terrain, you can choose a wheeled one. Finally, choose a drill rig that takes into account both efficiency and durability according to your budget.

We use a well-known domestic engine with low speed and high torque to ensure that the drill bit can efficiently break the rock, which can increase the efficiency by 20%-30% compared with ordinary engines. Our drill rods and drill bits are made of high-strength alloy steel. The service life is longer than that of ordinary steel, and the failure rate is lower, thus greatly saving drilling time, making drilling efficiency higher and hole formation faster.

This is a new generation of water well drilling rig. We have made many improvements in operation and control. It is equipped with a humanized controller and a display screen that displays drilling parameters in real time for easy viewing by operators. It also has anti-drilling protection, which greatly reduces the difficulty of operation.

We use our own research and development, all of which are made of high-strength wear-resistant alloy materials, which have a longer service life and can reduce consumption costs. In addition, when you purchase our drilling rigs, you can also pre-order accessories at the same time to get more discounts. Our inventory of commonly used wearing parts, such as drill bits, drill rods, and seals, is sufficient, and we can provide a stable, long-term supply to meet your needs.

The quality of core components determines the life and performance of the water drilling machine. We only use domestic high-end engines such as Weichai, Yuchai, or imported engines such as Cummins. Domestic engines have more advantages in cost performance and after-sales service. In addition, our hydraulic pumps are international brands such as Rexroth and Parker, ensuring the efficiency and stability of the hydraulic system. We spare no expense on core components and also achieve the best configuration for other components, aiming to provide you with more cost-effective equipment.