Underwater Cleaning Robot

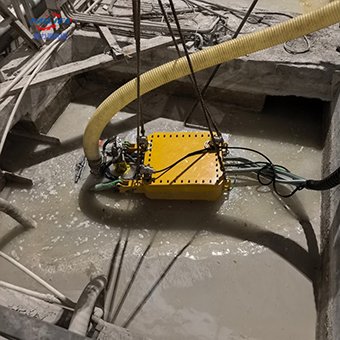

The frame of the Pailien dredging robot is made of Q345D carbon steel, which can adapt to harsh working environments. It replaces manual labor in entering confined spaces such as oil tanks and culverts for dredging operations.

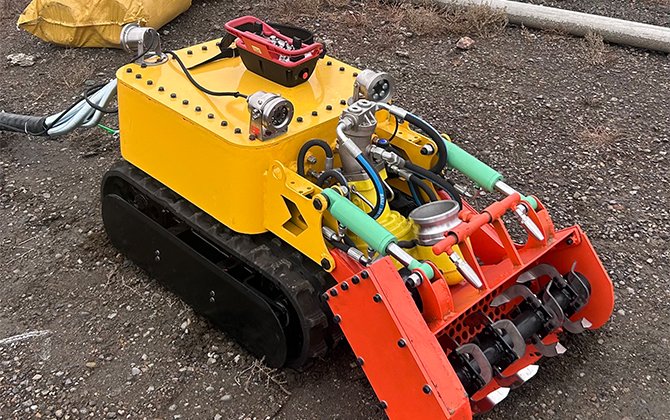

- Adopting a tracked chassis design, it offers greater stability during movement.

- Equipped with a high-definition camera, front and rear lights, and safe and efficient remote control operation.

- The main motor, winch, and distribution box are all equipped with explosion-proof systems.

- Its compact size allows for flexible movement in confined spaces.

Your Trusted Underwater Cleaning Robot Supplier in China

Through advanced autonomous control, sensors and dredging technology, the underwater cleaning robot developed by Pailien can independently perform dredging operations, improve work efficiency and reduce the impact on the environment. These underwater cleaning robots can work in different environments, such as rivers, canals, lakes, reservoirs, industrial wastewater treatment ponds, urban sewer systems, etc., and ensure the accuracy and efficiency of dredging operations through autonomous navigation, positioning, data collection and analysis.

Underwater Cleaning Robot by Features

Mainly used for dredging of rivers, canals and other waterways.

Mainly used for dredging of lakes, reservoirs, and industrial wastewater treatment ponds.

Responsible for cleaning up floating debris on the water surface.

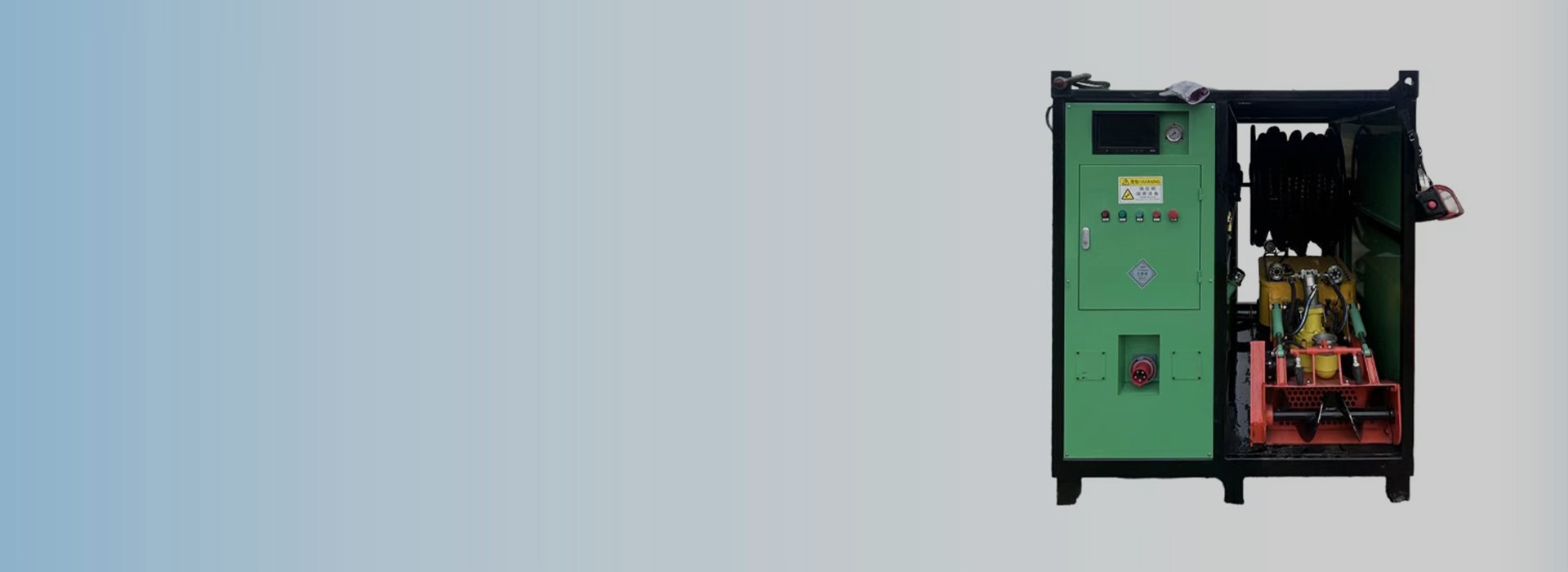

Equipped with professional monitoring and explosion-proof systems, suitable for dredging in petrochemical plants.

The machine is compact and easy to move, making it suitable for use in confined spaces such as municipal pipelines.

Framework of Underwater Cleaning Robot

The underwater cleaning robot mainly consists of a waterproof camera, a high-pressure flushing device, a winch, a tracked chassis, a remote control, and a slurry pump.

The dedicated waterproof camera is pressure-resistant, corrosion-resistant, and fog-proof, and can transmit images of underwater siltation, robot operation posture, and the location of surrounding obstacles to the onshore control console in real time.

The system pressurizes water to create a high-pressure jet, using the impact force of the water flow to break down and loosen the silt. This, combined with the suction from the main dredging unit, completes the dredging operation.

The electrical control cabinet and cable retraction device are integrated into one unit, which can be automatically recycled, making construction safe and convenient.

With strong load-bearing capacity, it meets the heavy-duty operation requirements such as large-scale river dredging and deep sludge removal in industrial sedimentation tanks, and solves the problems of insufficient load-bearing capacity and easy slippage of wheeled chassis.

Operators can remotely control the robot’s direction of travel, as well as start/stop and adjust parameters of the core dredging unit, using the joystick and buttons on the remote control.

Its main responsibility is to suck up silt and discharge it into designated recycling areas.

Underwater Cleaning Robot High-Definition Display Screen

The display screen can simultaneously show real-time images captured by an underwater camera, with a resolution of 1080P or higher. Even in turbid water, it can clearly reproduce details such as the distribution of silt, the robot’s working posture, and the location of underwater structures. Operators can accurately identify key areas for silt removal through the visuals without entering the water, guiding the robot to adjust its travel route and working angle, avoiding blind operation.

Underwater Cleaning Robot Hydraulic Motor

The underwater cleaning robot can operate at depths of tens or even hundreds of meters. The hydraulic motor adopts a fully sealed waterproof structure, which can withstand the high-pressure environment underwater and prevent oil leakage and water intrusion. At the same time, the motor shell is made of stainless steel or anti-corrosion coating material, which can resist the erosion of acid and alkaline sewage and water with high silt concentration, extend the service life of the equipment, and is suitable for multiple scenarios such as municipal pipe networks, industrial sedimentation tanks, and marine ports.

A Guide to Underwater Cleaning Robot

First, it is necessary to clarify the applicable scope of the underwater cleaning robot and the specific dimensions of the target pipeline or water area to ensure that the selected underwater cleaning robot can meet the operational requirements.

During dredging operations, it is necessary to monitor the working status and cleaning effect of the underwater cleaning robot in real time. Information such as the robot’s location, speed, and amount of dredging work can be viewed in real time through a controller or remote monitoring system.

After operating in highly corrosive environments such as acidic or alkaline wastewater and seawater, underwater cleaning robots need to be cleaned with a neutral detergent and then rinsed with clean water to avoid leaving any corrosive residue.

Why Choose the Pailien Underwater Cleaning Robot

Pailien is a leading manufacturer of underwater cleaning robots. Our underwater cleaning robots have obtained CE certification from EU countries. The body is made of Q345D carbon steel, enabling it to withstand harsh outdoor working environments and ensuring operational stability. We can also provide customized services to meet your specific needs, such as high-concentration sludge environments or chemical scenarios with high explosion-proof requirements, by customizing and adjusting robot size, power parameters, and operating modules. The Pailien underwater cleaning robot can work in hazardous environments, avoiding the safety risks and accidental injuries that may be caused by manual dredging.

What Services Can Pailien Provide for You

Our underwater cleaning robots not only cover more than 30 provinces and municipalities in China, but are also exported to many countries and regions in Europe, America, and Africa. They are adaptable to the construction standards and environmental regulations of different countries and possess a mature cross-border logistics and customs clearance service system. We have established a multi-regional after-sales network to provide 24-hour technical consultation. We also maintain a sufficient stock of spare parts such as seals, filters, and blades to minimize your equipment downtime losses. In addition, we can provide value-added services such as operation training and maintenance guidance to help you quickly get started with the equipment.

A customer in Shanxi Province, China, encountered a problem with the impeller of a robot used for cleaning fishponds, which was found to be severely worn and had excessive clearance.

After the winch smoothly lowers the underwater cleaning robot to the designated water depth, its built-in sonar, inertial navigation system, and GPS for shallow water areas are activated. Combined with real-time footage from an underwater waterproof camera, it completes underwater terrain scanning and locates the siltation area. Subsequently, a high-pressure flushing device first sprays high-pressure water to impact hardened silt and sediment, breaking down their structural strength. For stubborn silt, a hydraulically driven cutter further breaks up large particles, transforming the silt into a highly fluid slurry. A slurry pump then starts, creating a vacuum to draw the solid-liquid mixture into the pump body. Through high-pressure pipelines, the slurry is continuously pumped to storage tanks and transport vessels on the water surface. The camera feed allows operators to visually monitor the dredging progress.

When an underwater cleaning robot was cleaning fishponds in Shanxi Province, China, its sensor probes were covered by debris, causing abnormal sensor data.

To ensure the dredging work is completed accurately, efficiently, and safely, it is necessary to have a clear understanding of the specific dimensions of the target pipeline and the characteristics of the silt in the target water area.

When selecting an underwater cleaning robot, we should consider the following aspects:

- Define the operating scenarios and working conditions: For small municipal pipelines, choose compact and flexible underwater cleaning robots; for rivers, lakes, and ports, choose large robots with high power and tracked chassis; for industrial sedimentation tanks and chemical wastewater tanks, consider explosion-proof and acid and alkali resistance levels, and choose fully sealed hydraulic drive models, with 316 stainless steel or anti-corrosion coating as the preferred material for the machine body.

- Focus on verifying whether the slurry pump’s head and flow rate match the actual operational requirements to ensure efficient slurry delivery to the designated location. Simultaneously, pay attention to the crushing strength of the cutter head, ensuring it can handle the crushing of compacted sludge and large particles. For high-pressure flushing devices, it is recommended to select models with a water pressure range of 10–300 MPa and flexible adjustment capabilities to adapt to the cleaning needs of sludge with varying hardness.

- Overall cost-effectiveness and maintenance costs: 3. The equipment protection level must meet the IP68 standard to ensure stable operation in deep-water, high-pressure environments and eliminate the risk of water ingress; electrical components should have comprehensive overload and short-circuit protection functions to reduce the failure rate from the source. When selecting a brand, prioritize products with strong versatility and lower procurement costs for easily damaged parts such as seals, impellers, and track plates; at the same time, require manufacturers to provide a warranty of one year or more for key core components such as hydraulic motors and slurry pumps to reduce later maintenance costs.

- Choosing an underwater cleaning robot isn’t about getting the most expensive one; the key is its suitability for the specific working conditions. It’s recommended to prioritize suppliers with a good industry reputation, rapid after-sales service response, and transparent technical specifications to ensure long-term stable operation and ongoing support.