Diamond Core Drilling Rigs

Diamond coring rigs have advantages such as high coring efficiency, drilling accuracy, and applicability to hard strata, making them irreplaceable in geological exploration, mineral resource assessment, and engineering surveying.

- Diamond drill bits, with high hardness, can drill through hard rock layers.

- Advanced core sampling and preservation technology ensures highly intact and continuous core samples.

- Suitable for hard and complex rock layers such as granite, basalt, and metamorphic rocks.

- High accuracy of core data provides a reliable basis for subsequent work.

Your Trusted Diamond Core Drilling Rig Supplier in China

As a diamond coring rig manufacturer with over ten years of experience, we continuously research and optimize our rigs to enhance their service capabilities. In particular, our high-torque diamond hydraulic coring drill bit power head provides excellent drilling stability while ensuring sampling accuracy and core recovery rates.

Furthermore, we offer a comprehensive range of optional equipment, including coring drill rods, diamond drill bits, mud pumps, and core collection boxes, to meet diverse customer needs.

Various Types of Diamond Core Drilling Rigs

Primarily used for geological and mineral exploration and resource assessment. Diamond core drilling rigs can obtain complete core samples, which are invaluable for accurately analyzing mineral distribution and reserves.

The main actions, such as lifting drill tools, connecting and disassembling drill rods, drilling, and outrigger support, are all driven by a high-pressure hydraulic system, making the machine operation more stable and precise.

Suitable for soft and uneven terrain such as mountain slopes and gravel areas. It features a tracked system, providing off-road capability and excellent maneuverability.

Suitable for drilling depths of 300-1000 meters and drilling diameters of 75-200mm.

The engine, drill rod, drill bit, control system, and other components of the drilling rig can all be customized to suit your different working conditions.

The drilling rig can be equipped with a high-altitude engine and an enhanced cooling system, ensuring stable operation even in harsh environments with high altitudes and large temperature differences.

It can integrate a generator for use in remote areas without external power. It can both power the drilling rig and provide lighting for nighttime operations.

It employs low-noise, low-vibration drilling techniques, and the drill bit is designed to minimize rock disturbance. It is suitable for drilling operations with stringent environmental requirements.

Framework of Diamond Core Drilling Rig

A diamond core drilling rig mainly consists of a power system, a drill rod system, a cooling system, a rod lifting system, a crawler walking system, and an operation and control platform.

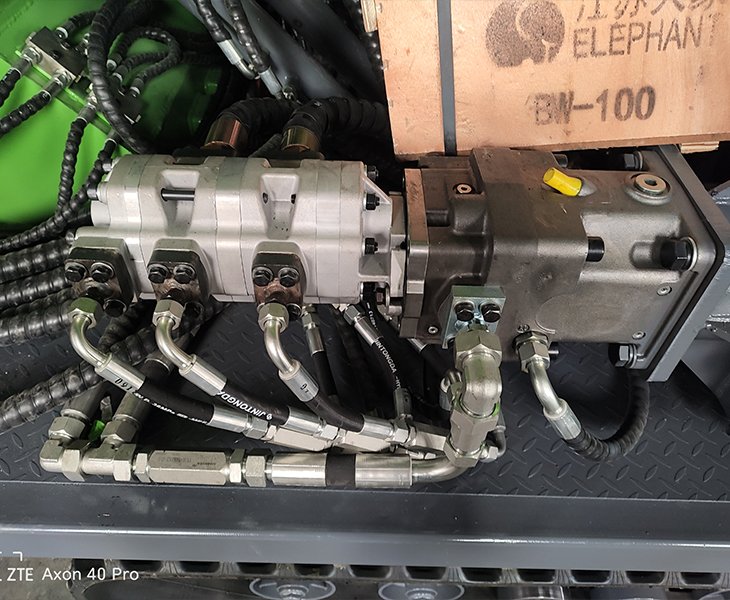

The power system, mainly composed of an engine, hydraulic pump station, and electrical control unit, is the core of the drilling rig,providing power to the core drilling rig.

The drill pipe system is the backbone of the entire drilling rig, responsible for core extraction and the transmission of torque and pressure. Pailien’s diamond core drilling rigs utilize high-hardness synthetic diamond drill bits, offering superior wear resistance.

This is the system that ensures the normal operation of the drilling rig. Cooling lubricant is forced into the gap between the drill bit and the drill string, thereby cooling the diamond drill bit during high-speed drilling, lubricating the drill string, and reducing friction.

Composed of components such as a winch, wire rope, and hook, it is used to raise and lower drill pipes during the drilling process of a diamond core drilling rig. The raising speed is adjustable, and safety is very high.

It adopts a tracked walking method, which has great ground adhesion. This not only makes drilling operations more stable, but also makes it suitable for complex working conditions such as mountains and swamps.

It adopts an integrated operation panel, which makes operation simple and efficient through a one-command-one-action control method.

Diamond Core Drilling Rig Slurry Pump

The mud pump in a diamond core drilling rig provides a high-pressure mud flow for the entire drilling process, ensuring mud circulation. Using a mud pump eliminates the need for complex air compressors and double-walled drill pipes, thus improving the accuracy of diamond core drilling rig sampling. The mud pump in the Pailien diamond core drilling rig uses a variable frequency drive (VFD) to adjust flow and pressure, and it can also integrate a thermal system to raise and maintain mud temperature, improving drilling efficiency.

Dimaond Drilling Rig Drill Pipe

Diamond coring rigs use a double-tube coring rod. The inner tube is used for core sampling. The design of the drill rod in the Palien diamond drill rig provides the core with an independent and fixed space, isolated from the flushing fluid. This design ensures the core remains intact and uncontaminated by other materials. The outer tube transmits torque and axial force to the drill bit for drilling operations. Furthermore, the drill rods undergo special heat treatment, extending their service life.

Guide to Procuring

Before purchasing our diamond core drilling rig, please contact our sales manager first. We will recommend a suitable model after thoroughly understanding your specific geological conditions and requirements for using the diamond core drilling rig.

After fully understanding the working environment, target rock depth, and core sampling requirements of the diamond core drilling rig you will be using, we will discuss with our engineers to match the most suitable diamond core drilling rig model for you, as well as matching drill rods, drill bits, and other components.

Before finalizing the order for the diamond core drilling rig, we will reconfirm the rig parameters, configuration, and optional parameters for drill rods and other accessories with you, and sign a formal technical agreement and supply contract.

Company Advantage

Pailien Machinery is a manufacturer with over 10 years of experience producing diamond core drilling rigs. We update our rigs annually based on customer feedback and the latest global technologies, conducting in-depth research on integrated and control systems to improve machine ease of operation and safety. Our core components, such as engines and mud pumps, are sourced from top-tier brands and undergo rigorous quality control and screening to ensure the reliability and durability of our drilling rigs. Regarding after-sales service, we firmly believe that a transaction is just the beginning of cooperation. We will continuously follow up and monitor your usage, providing timely after-sales response so you no longer need to worry about post-purchase issues.

Your Professional Diamond Core Drilling Rigs Manufacturer in China

Our expertise extends beyond hardware like the rigs themselves. We also excel in our customer service and other service aspects. Our sales representatives undergo approximately two years of training in diamond core drilling rigs before serving you, and they have all worked on-site to truly understand the rig’s operational status. Therefore, after you describe your exploration depth and environmental requirements, they can design and match the most suitable machine for you, avoiding compatibility issues from the outset. Furthermore, we have an experienced team of engineers to assist our sales staff in providing excellent service.

When a diamond core drill experiences core blockage, it is usually caused by encountering a layer of gravel, incorrect adjustment of drill pressure and speed parameters, malfunction of the mud pump, or improper matching of drill rods. The following methods can typically be used to troubleshoot and resolve the issue.

When working with a diamond core drill, a broken drill rod can significantly impact the progress of the project and may also pose a safety hazard. This is usually caused by factors such as encountering hard rock formations, improper operation, worn threads, or improper handling of stuck drill bits.

We want our drilling rigs to be both highly flexible and precise, while also being incredibly easy to operate. This is precisely what we strived to achieve during the design and development process.

To maximize the lifespan of our diamond core drilling rigs, regular maintenance is crucial. Our rigs are designed with maintenance and upkeep in mind.

The mud pumps we configure for diamond core drilling rigs are selected based on a comprehensive calculation of your core diameter, drilling depth, and formation conditions. These parameters have been verified through extensive practical application to ensure effective circulation of the flushing fluid.